In hull form development, based on the prototype (type ship), the hull form is determined by comprehensively considering propulsive performance, maneuverability, seaworthiness, and other factors to satisfy various requirements depending on the intended use of the ship. The efficient and sophisticated development of such a ship requires specialized knowledge and technology in ship hydrodynamics. In particular, propulsion performance is an important factor that directly affects the competitiveness of a ship. In many cases, strict requirements for fuel consumption are set, so we devote a lot of time to studying this issue.

Hull Form Design

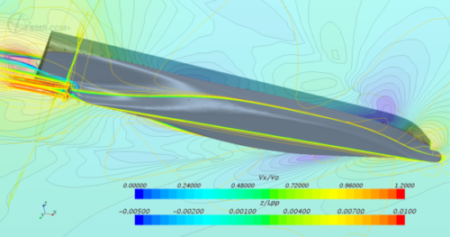

Hull form development aims to reduce wave drag and viscous resistance while meeting the required volume and equipment layout, so that the horsepower generated by the main engine can be efficiently used for the hull.

Hull form development aims to reduce wave drag and viscous resistance while meeting the required volume and equipment layout, so that the horsepower generated by the main engine can be efficiently used for the hull.

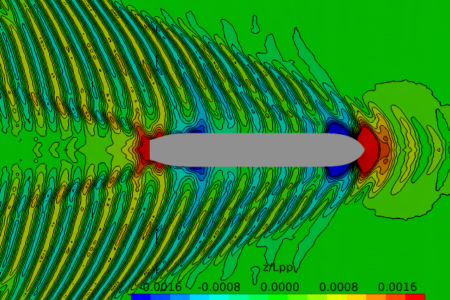

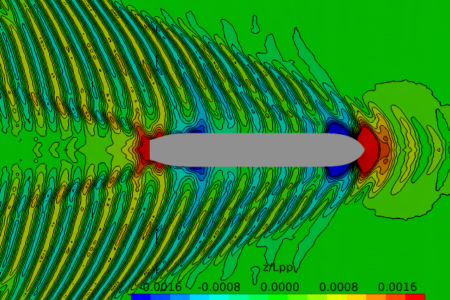

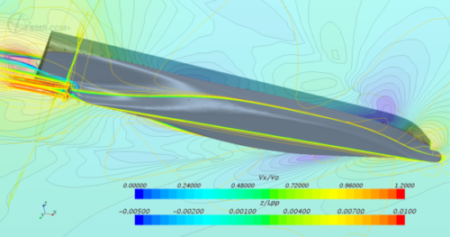

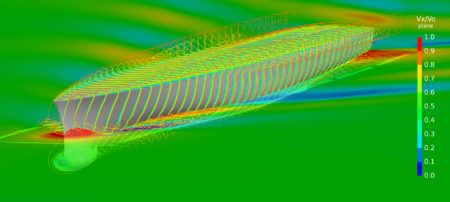

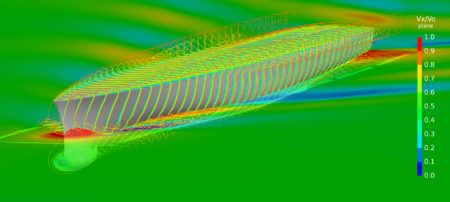

In addition, since excessive hydrodynamic force fluctuations and cavitation generated by the propeller rotating behind the hull may cause hull vibration and noise, we work to ensure that the hull wake flowing into the propeller is smooth and uniform.

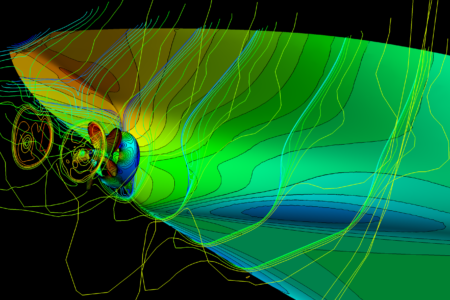

Hull form evaluation is carried out using Computational Fluid Dynamics (CFD).

Hull form evaluation is carried out using Computational Fluid Dynamics (CFD).

Although CFD uses tools that have been evaluated to a certain degree, it is not possible to obtain an exact solution for use in ordinary design due to limitations in computation time and other factors. Therefore, an experimental sense is also required to interpret the calculation results.

We can increase the reliability of CFD by using CFD together with a wealth of model test results. Hull forms obtained through hull form development can also be evaluated more reliably by conducting tank tests.

We design and develop various types of ships, from commercial ships to survey ships that require quietness, ships for public institutions and universities, fishing ships, patrol ships, and ships for the navy.

We design and develop various types of ships, from commercial ships to survey ships that require quietness, ships for public institutions and universities, fishing ships, patrol ships, and ships for the navy.

Recently, we are also working on projects for shipyards and shipping companies besides the Mitsui E&S Group.

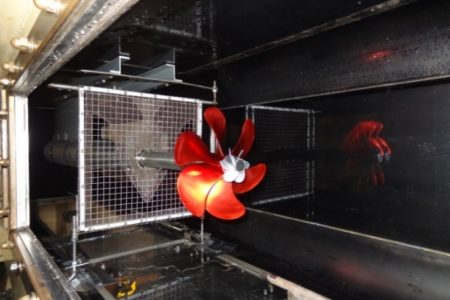

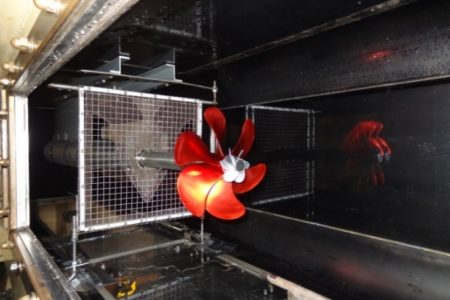

We develop various energy-saving devices and conduct tank tests.

We develop various energy-saving devices and conduct tank tests.

Energy-saving devices operate in a complex flow field due to hull wakes and propellers, so it is difficult to estimate their performance. But those devices help to save 5% to 7% energy if we can design them to match wakes.

Utilizing Computational Fluid Dynamics (CFD), we carry out efficient design based on information such as hydrodynamic forces, flow field, and pressure.

We can also produce a model ship based on the designed shape and conduct a tank test to make an even more reliable evaluation.

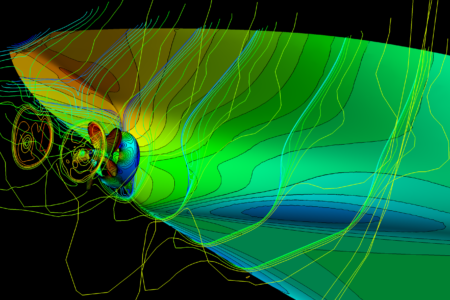

We have developed Advanced Propeller Boss Cap Fins (the new PBCF) through joint research with MOL and MOL Techno-Trade.

We have developed Advanced Propeller Boss Cap Fins (the new PBCF) through joint research with MOL and MOL Techno-Trade.

The new PBCF is an energy-saving device installed on the propeller of a ship. It reduces resistance by eliminating hub vortices, improves propulsion efficiency by stopping the damming effect of the fins, and reduces torque by the lift force generated by the fins. In developing the new PBCF, we used CFD calculations and tank tests and achieved a fuel efficiency reduction of approximately 5%, which is +2% compared to the conventional PBCF.

For details, please refer to the page of MOL Techno-Trade Co., Ltd.PBCF Official Website MOL Techno-Trade Co., Ltd.

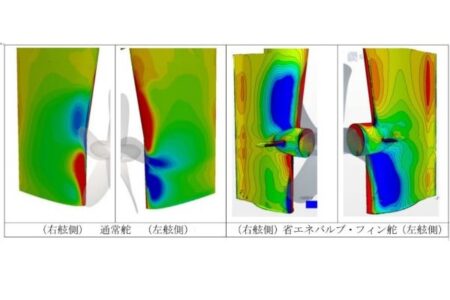

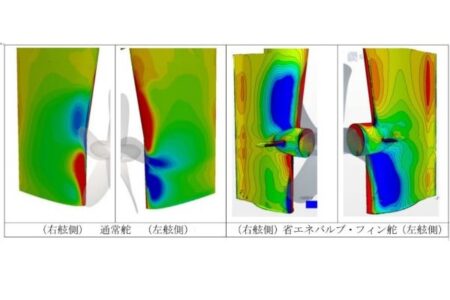

Through joint research with Mitsui O.S.K., Japan Hamworthy Co. Ltd., and MOL Techno-Trade, Ltd., we developed an energy-saving valve and fin rudder.

Through joint research with Mitsui O.S.K., Japan Hamworthy Co. Ltd., and MOL Techno-Trade, Ltd., we developed an energy-saving valve and fin rudder.

In the development of energy-saving valve and fin rudders, we took advantage of the rudder performance of JHC, a manufacturer specializing in rudders with parallel section at trailing part (RUPAS), such as fish trail rudders, to improve energy-saving performance (improved horsepower). The features of this product are as follows.

1) To recover the propeller's swirling flow, the reaction shape is a high-thrust blade and the rudder horn is also twisted. (Energy-saving valves and fin rudders increase negative pressure, contributing to an increase in propulsion force.)

2) The end plate under the rudder is made smaller to reduce resistance and block the propeller swirling flow.

3) The front of the large central valve is also flat to reduce the propeller inflow speed and increase the propeller efficiency.

For details, please refer to the page of MOL Techno-Trade Co., Ltd.

Information MOL Techno-Trade Co., Ltd.